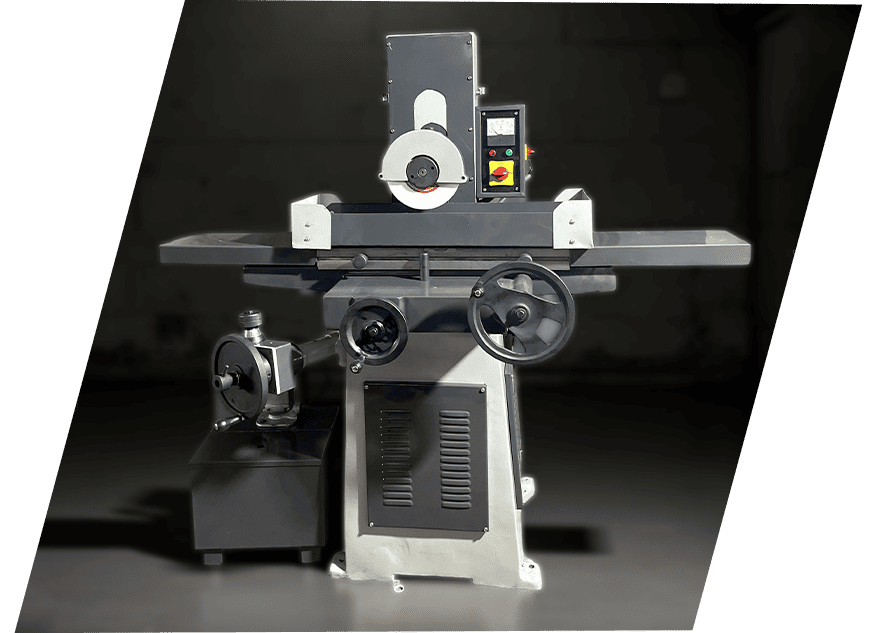

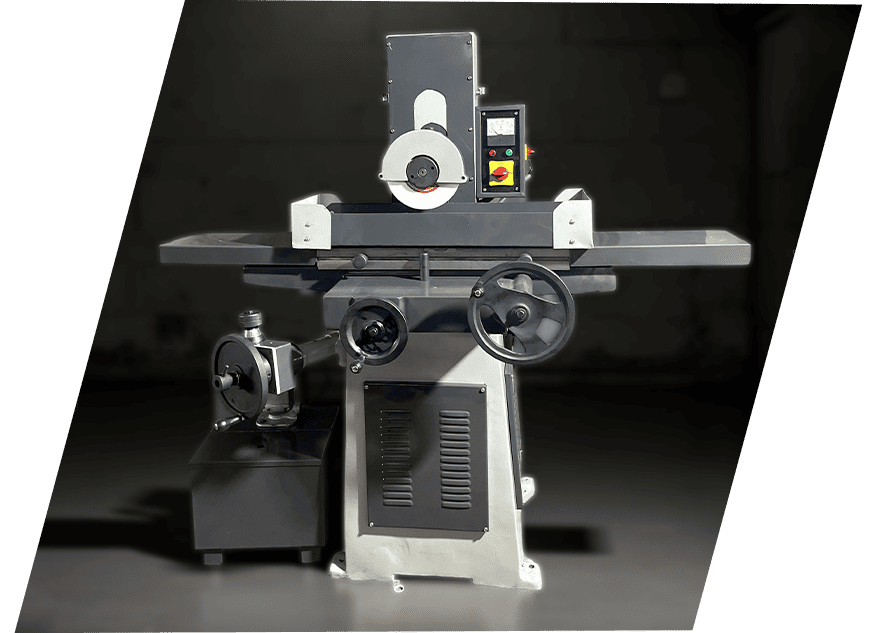

About Grinding Machine

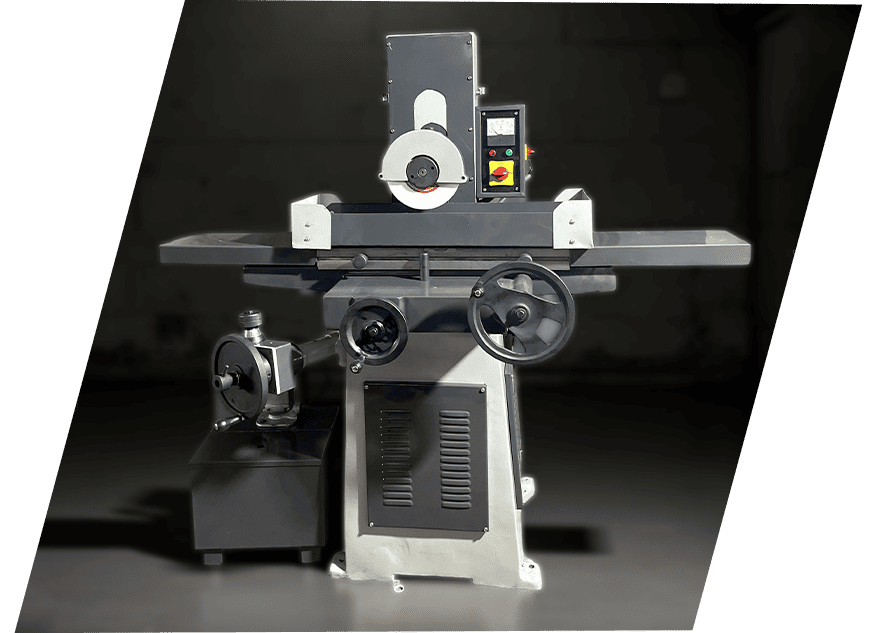

Manual Surface Grinding Machine Engineered

Meet the HM500x200, a robust and reliable manual surface grinding machine designed for precision, performance, and durability. Perfect for tool rooms, die shops, and precision component manufacturers, this machine is the ideal companion for achieving mirror-finish flatness and tight tolerances.

Built to Last

Heavy-Duty Structure: Fabricated from graded cast iron for maximum damping and rigidity

V & Flat Guideways: Precisely hand-scraped for consistent movement

Coolant System: Integrated system to maintain low temperatures during grinding

Electric Panel: Operator-friendly with safety interlocks

Structure

Made from heavy-duty, high-grade cast iron

Hand-scraped base for high accuracy and fine tolerance

Reciprocating table with V & Flat guideways for smooth movement

Wheel Head

Spindle is hardened and ground for durability

Fitted with precision ball bearings (SKF or NACHI)

Uses imported grease for long, trouble-free operation

Micro Feed System

Wheel head slide moves on the right side of the base

Standard feed least count: 0.01 mm

Micro feed least count: 0.002 mm

Structure

Made from heavy-duty, high-grade cast iron

Hand-scraped base for high accuracy and fine tolerance

Reciprocating table with V & Flat guideways for smooth movement

Wheel Head

Spindle is hardened and ground for durability

Fitted with precision ball bearings (SKF or NACHI)

Uses imported grease for long, trouble-free operation

Micro Feed System

Wheel head slide moves on the right side of the base

Standard feed least count: 0.01 mm

Micro feed least count: 0.002 mm

Standard Accessories

Optional Accessories

The machine is built of heavy-cuty high-grade cast iron. Base is built of hand scraped to achieve fine tolerance & accuracy

- Total Power: 1H.P./0.75kw

- Net Weight: 650 Kg

Standard Accessories

1. Diamond Dresser With Holder

2. Wheel Puller

3. One Grinding Wheel With Flange

4. Electric Motor With Starter

5. Magnet Chuck Lock Piece.

Optional Accessories

1. Permanent Magnec Chuck

2. Coolant System

3. Machine Lamp (230 V Ac)

4. Lubricaon Pump

5. DRO

6. Dust Collector

7. Tool Kit

8. Electric Magnetic Chuck

9. Coolant System With Magnetic

separator & paper band filter.

10. Radius & Angular Wheel Truing

attachment.

11. Vice – Plain, Sine, Swivel & Universal.

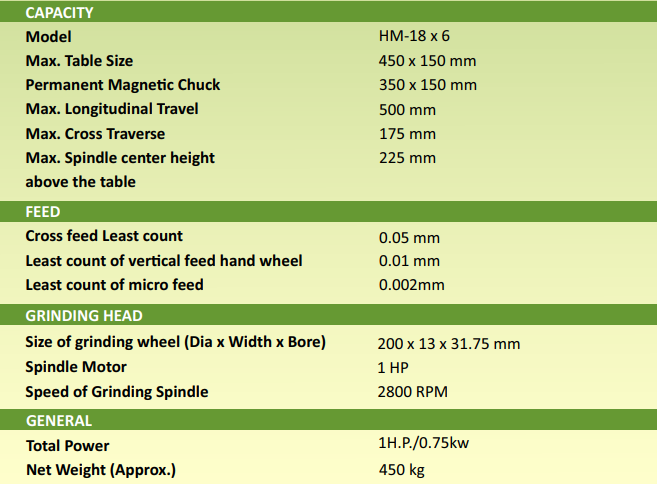

SPECIFICATIONS

CAPACITY

| Parameter | Value |

|---|---|

| Model | HM-18 x 6 |

| Max. Table Size | 450 x 150 mm |

| Permanent Magnetic Chuck | 350 x 150 mm |

| Max. Longitudinal Travel | 500 mm |

| Max. Cross Traverse | 175 mm |

| Max. Spindle Center Height (above table) | 225 mm |

FEED

| Parameter | Value |

|---|---|

| Cross Feed Least Count | 0.05 mm |

| Least Count of Vertical Feed Hand Wheel | 0.01 mm |

| Least Count of Micro Feed | 0.002 mm |

GRINDING HEAD

| Parameter | Value |

|---|---|

| Size of Grinding Wheel (Dia x Width x Bore) | 200 x 13 x 31.75 mm |

| Spindle Motor | 1 HP |

| Speed of Grinding Spindle | 2800 RPM |

GENERAL

| Parameter | Value |

|---|---|

| Total Power | 1 HP / 0.75 kW |

| Net Weight (Approx.) | 450 kg |

Wheel Head

Spindle is hardened and ground for durability

Fitted with precision ball bearings (SKF or NACHI)

Uses imported grease for long, trouble-free operation

Driven by flange-mounted motor via flexible coupling

Micro Feed System

Wheel head slide moves on the right side of the base

Standard feed least count: 0.01 mm

Micro feed least count: 0.002 mm