About Grinding Machine

Hydraulic Surface Grinding Machine – Model: HM600x300H

The HM600x300H is a high-precision hydraulic surface grinding machine designed to meet the rigorous demands of modern industrial applications. Engineered with a robust structure and advanced features, this model ensures superior grinding accuracy, surface finish, and long-term performance reliability.

Key Features

Table Size: 600mm x 300mm

Heavy-Duty Construction: Built with premium-grade cast iron for high rigidity, low vibration and excellent structural stability.

Hydraulic Table Movement: Smooth and consistent longitudinal table reciprocation powered by a reliable hydraulic system for effortless operation.

Precision Spindle Assembly: Hardened and ground spindle mounted on high-precision antifriction bearings (SKF/NACHI), ensuring flawless rotation and longer bearing life.

Vertical Micro Feed System: Equipped with fine-feed control for precise vertical movement of the grinding wheel head, ideal for ultra-accurate surface finishing.

V & Flat Guideways: Precision hand-scraped guideways with Turcite lining for smooth sliding action and reduced wear over time.

Efficient Transmission: Flange-mounted motor connected through flexible couplings for consistent power transfer and reduced vibration.

Optional Coolant System: Enhances grinding performance by cooling the workpiece and wheel, reducing thermal distortion.

Applications

Die and Mold Shops

Precision Tooling Components

Surface Finishing of Flat Parts

Automobile and Aerospace Industries

Metalworking and Fabrication Workshops

Why Choose HM600x300H?

Accurate & Repeatable Grinding Results

Hydraulic Efficiency for Higher Output

Durable, Rigid & Low-Maintenance Design

User-Friendly Operation & Controls

Supported by Expert Service & Spare Parts Availability

Standard Accessories

1. Diamond Dresser With Holder

2. Wheel Puller

3. One Grinding Wheel With Flange

4. Electric Motor With Starter

5. Magnet Chuck Lock Piece.

Optional Accessories

1. Permanent Magnec Chuck

2. Coolant System

3. Machine Lamp (230 V Ac)

4. Lubricaon Pump

5. DRO

6. Dust Collector

7. Tool Kit

8. Electric Magnetic Chuck

9. Coolant System With Magnetic

separator & paper band filter.

10. Radius & Angular Wheel Truing

attachment.

11. Vice – Plain, Sine, Swivel & Universal.

Standard Accessories

Optional Accessories

The machine is built of heavy-cuty high-grade cast iron. Base is built of hand scraped to achieve fine tolerance & accuracy

- Total Power: 1H.P./0.75kw

- Net Weight: 650 Kg

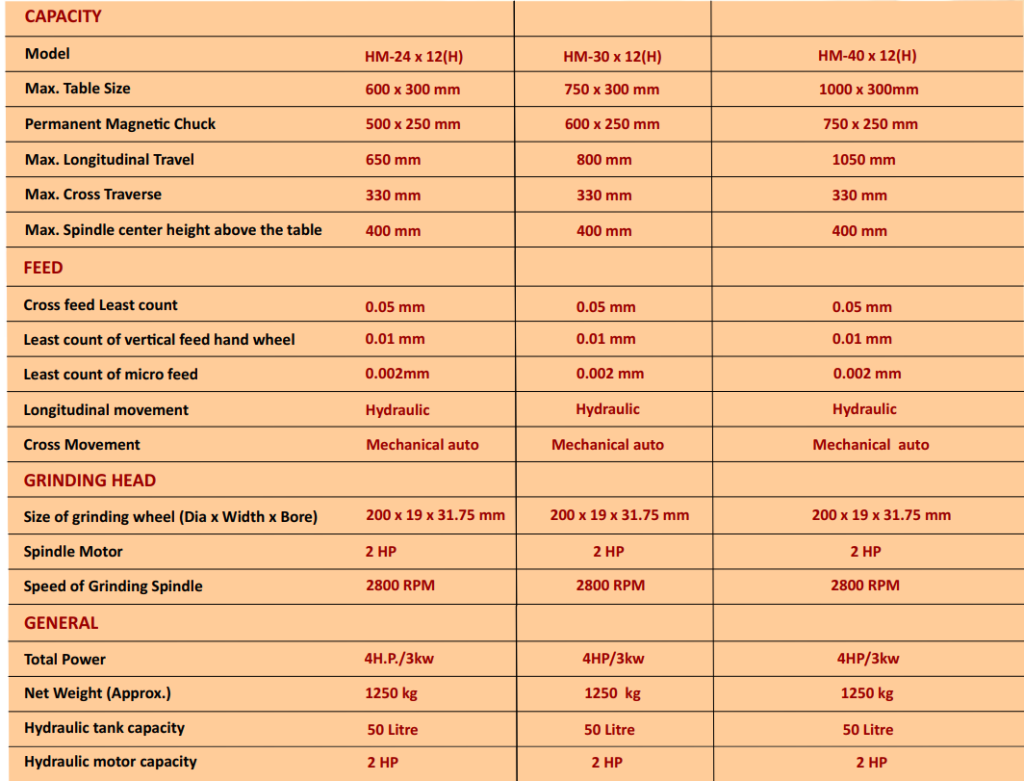

SPECIFICATIONS

CAPACITY

| Specification | HM-24 x 12 | HM-30 x 12 | HM-40 x 12 |

|---|---|---|---|

| Max. Table Size | 600 x 300 mm | 750 x 300 mm | 1000 x 300 mm |

| Permanent Magnetic Chuck | 500 x 250 mm | 600 x 250 mm | 750 x 250 mm |

| Max. Longitudinal Travel | 650 mm | 800 mm | 1050 mm |

| Max. Cross Traverse | 330 mm | 330 mm | 330 mm |

| Max. Spindle Center Height | 400 mm | 400 mm | 400 mm |

FEED

| Specification | All Models |

|---|---|

| Cross Feed Least Count | 0.05 mm |

| Least Count of Vertical Feed Hand Wheel | 0.01 mm |

| Least Count of Micro Feed | 0.002 mm |

GRINDING HEAD

| Specification | All Models |

|---|---|

| Size of Grinding Wheel | 200 x 19 x 31.75 mm |

| Spindle Motor | 2 HP |

| Speed of Grinding Spindle | 2800 RPM |

GENERAL

| Specification | All Models |

|---|---|

| Total Power | 2 H.P./1.5 kW |

| Net Weight (Approx.) | 1250 kg |

CAPACITY

| Specification | HM-24 x 12 | HM-30 x 12 | HM-40 x 12 |

|---|---|---|---|

| Max. Table Size | 600 x 300 mm | 750 x 300 mm | 1000 x 300 mm |

| Permanent Magnetic Chuck | 500 x 250 mm | 600 x 250 mm | 750 x 250 mm |

| Max. Longitudinal Travel | 650 mm | 800 mm | 1050 mm |

| Max. Cross Traverse | 330 mm | 330 mm | 330 mm |

| Max. Spindle Center Height | 400 mm | 400 mm | 400 mm |

FEED

| Specification | All Models |

|---|---|

| Cross Feed Least Count | 0.05 mm |

| Least Count of Vertical Feed Hand Wheel | 0.01 mm |

| Least Count of Micro Feed | 0.002 mm |

GRINDING HEAD

| Specification | All Models |

|---|---|

| Size of Grinding Wheel | 200 x 19 x 31.75 mm |

| Spindle Motor | 2 HP |

| Speed of Grinding Spindle | 2800 RPM |

GENERAL

| Specification | All Models |

|---|---|

| Total Power | 2 H.P./1.5 kW |

| Net Weight (Approx.) | 1250 kg |